Oppressive Balling Machine

Maximum feed:>30mesh

production capacity:1.5-25(t/h)

Features:It has the characteristics of high rate of ball formation, good shape of granule, high strength, less dust, easy cleaning and maintenance.

Applicable materials:It can be widely used in pharmaceutical, chemical, soda ash, fertilizer, feed, plastic additives, food, cosmetics and other dry powder granulation occasions.

24-hour service hotline

Oppressive Balling Machine product description

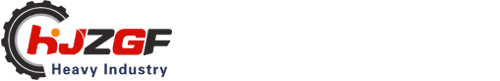

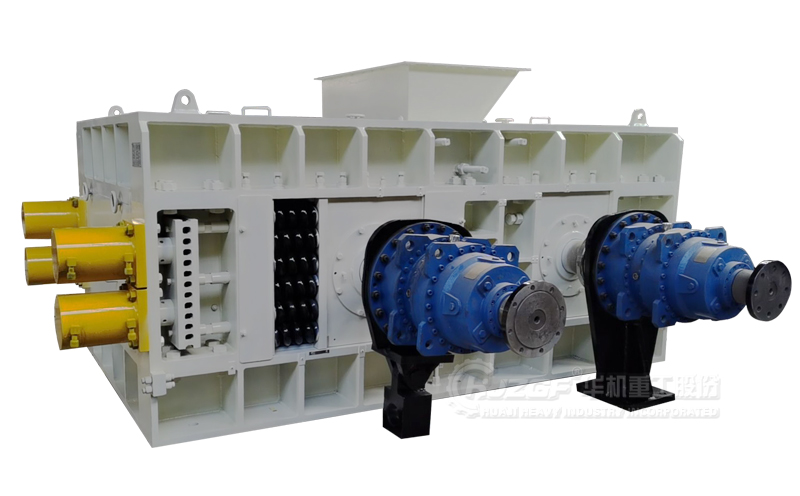

GGZ series dry high pressure pelletizing machine is the second generation of dry roller pelletizing machine which is researched and designed by our company on the basis of absorbing the advanced technology from abroad. Due to the adoption of dry extrusion and forced feeding technology, the powdery material with water content <5% can be compressed into granule shape. It has the characteristics of high pelletizing rate, good shape of granule, high strength, less dust, easy cleaning and maintenance. It can be widely used in medicine, chemical industry, soda ash, fertilizer, feed, plastic additives, food, cosmetics and other dry powder granulation occasions.

1、Materials are forced to be compressed and molded by mechanical pressure, without adding any wetting agent, product purity is guaranteed.

2, dry powder direct granulation, without subsequent drying process, more conducive to the convergence of the existing production process and transformation.

3、High particle strength, the specific gravity of the pile can be increased by 1.5-3 times, especially suitable for increasing the specific gravity of the product pile of occasions.

4、It can control the environmental pollution, reduce the waste of powder and packaging costs, and improve the product transportation capacity.

5、Compact structure, easy maintenance, simple operation, short process flow, low energy consumption, high efficiency, low failure rate, suitable for a wide range of raw materials.

Oppressive Balling Machine working principle

Powder material from the hopper through the spiral feeder quantitatively and uniformly added to the main hopper, so that it maintains a stable material level, and then by the longitudinal cone screw machine for pre-compression of the powder, and sent to the two pressure rollers formed in the molding cavity; two pressure rollers uniformly distributed on the surface of the same shape of the mold, through the power transmission, so that the two pressure rollers at the same speed, synchronization, phase rotation, the conveyor of the powder is bitten into the roller cavity forced compression, extrusion, powder After compression and molding, the powder will fall down under the action of elasticity and gravity, and a small amount of non-dislodged material will be scraped down by the scraper. By changing the roll surface mold form, can get ball, strip, flat ball material, according to the particle size requirements of the sieve, grading, meet the quality requirements of the granular products transported away, sieve the fine powder back to the main material warehouse to form a closed-circuit cycle of granulation.Oppressive Balling Machine Technical Parameters

| number | Model |

Pressure roller diameter (mm) |

Roller width (mm) |

rpm (m/s) |

production capacity (t/h) |

power (Kw) |

| 1 | GGZ10 | 650 | 500 | 0.8-1.8 | 10 | 110 |

| 2 | GGZ20 | 800 | 650 | 20 | 250 | |

| 3 | GGZ30 | 900 | 800 | 30 | 370 | |

| 4 | GGZ50 | 1000 | 900 | 50 | 450 | |

| 5 | GGZ75 | 1200 | 1000 | 75 | 710 | |

| 6 | GGZ100 | 1500 | 1200 | 100 | 1000 | |

| 7 | GGZ130 | 1800 | 1600 | 130 | 1600 |

- durable

- make fast

- easy maintenance

- Few faults

- 24-hour sales hotline:+8618053687318

- get a quote

Recommended Products

Hotline:+8618053687318click to call

Copyright: Shandong Huaji Heavy Industry Co., Ltd. 24-hour service hotline:+8618053687318 E-mail:jczg@sdjiuchang.com