Granite Crusher

Maximum feed:<1200mm

production capacity:5-1000(t/h)

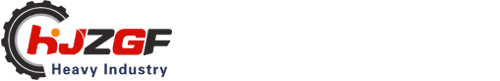

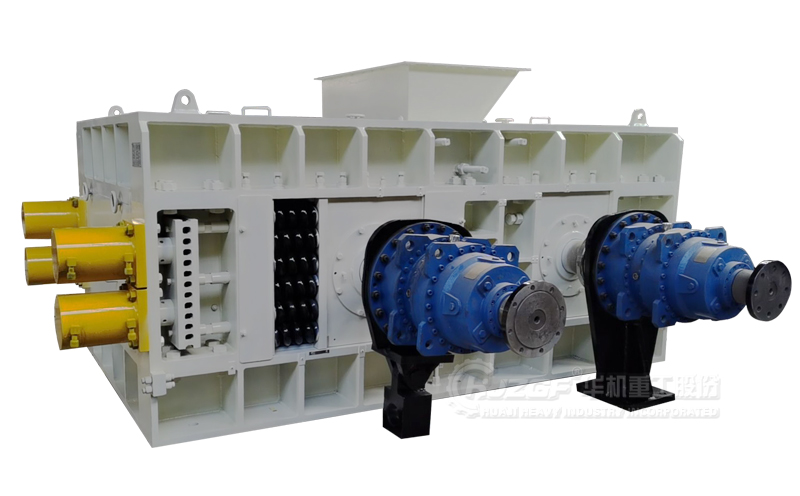

Features:Huaji Heavy Industry Granite Crusher is a high-performance and multifunctional crushing equipment. Due to the high demand for granite, this equipment is widely used in many fields such as metallurgy, chemical industry, machinery, and construction.

Applicable materials:Granite and other types of ores with compressive strength not exceeding 320MPa.

24-hour service hotline

Granite Crusher product description

Granite crusher is suitable for crushing hard materials (compressive strength<320Mpa), such as granite, iron ore, steel slag, phosphate rock, silicon ore, copper ore, limestone, quartz stone, ceramics, and solid materials with similar hardness. It is used for coarse crushing of large blocks in various beneficiation plants, stone plants, cement plants, etc. It has the characteristics of high crushing ratio, low maintenance cost, low power consumption, and reliable performance, and can be widely used in industries such as mining, stone factories, building materials, metallurgy, ceramics, etc.

The main advantages of this device are:

1. This equipment has a high crushing ratio, uniform discharge, low impurity content, and good crushing effect in the process of crushing granite.

2. In terms of production capacity, the high equipment configuration creates considerable economic benefits for users, and users are quite satisfied with this.

3. If the equipment malfunctions during operation, its protective device will function in a timely manner, thus ensuring high safety.

Granite Crusher working principle

The granite crusher is driven by an electric motor to drive the belt and pulley, which move the moving jaw up and down through an eccentric shaft. When the moving jaw rises, the angle between the elbow plate and the moving jaw increases, thereby pushing the jaw plate closer to the fixed jaw plate. At the same time, the material is crushed or chopped, achieving the purpose of crushing; When the moving jaw descends, the angle between the elbow plate and the moving jaw decreases. Under the action of the pull rod and spring, the moving jaw plate leaves the fixed jaw plate. At this time, the crushed material is discharged from the lower opening of the crushing chamber. With the continuous rotation of the electric motor, the moving jaw operates periodically to crush the material, breaking it into ideal particles and discharging them from the discharge port.Granite Crusher Technical Parameters

| Model |

Inlet size (mm) |

Feed size (mm) |

Output granularity (mm) |

production capacity (t/h) |

Motor power (Kw) |

| PEX-250×750 | 750×250 | 210 | 25-60 | 15-35 | 22 |

| PEX-250×1000 | 1000×250 | 210 | 25-60 | 16-45 | 30 |

| PEX-250×1200 | 1200×250 | 210 | 25-60 | 20-60 | 37 |

| PEX-300×1300 | 1300×300 | 260 | 25-90 | 25-90 | 45 |

| PEX-500×1500 | 1500×500 | 450 | 25-90 | 30-120 | 75 |

| PEX-500×2000 | 2000×500 | 450 | 25-100 | 40-120 | 90 |

- durable

- make fast

- easy maintenance

- Few faults

- 24-hour sales hotline:+8618053687318

- get a quote

Recommended Products

Hotline:+8618053687318click to call

Copyright: Shandong Huaji Heavy Industry Co., Ltd. 24-hour service hotline:+8618053687318 E-mail:jczg@sdjiuchang.com