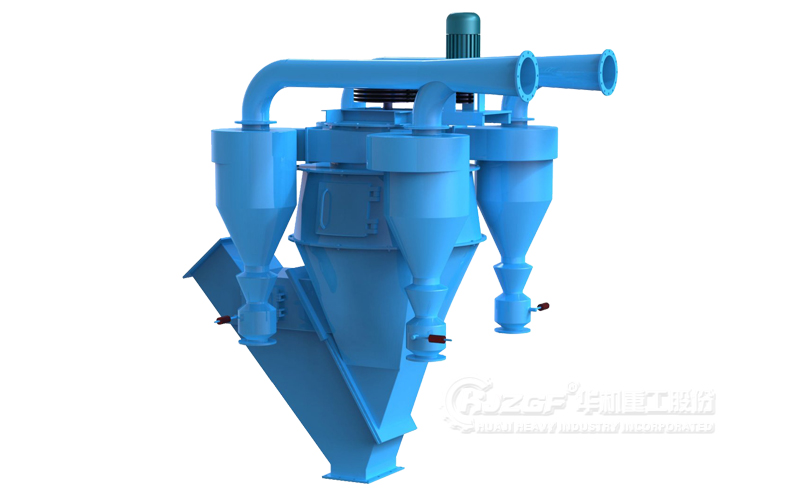

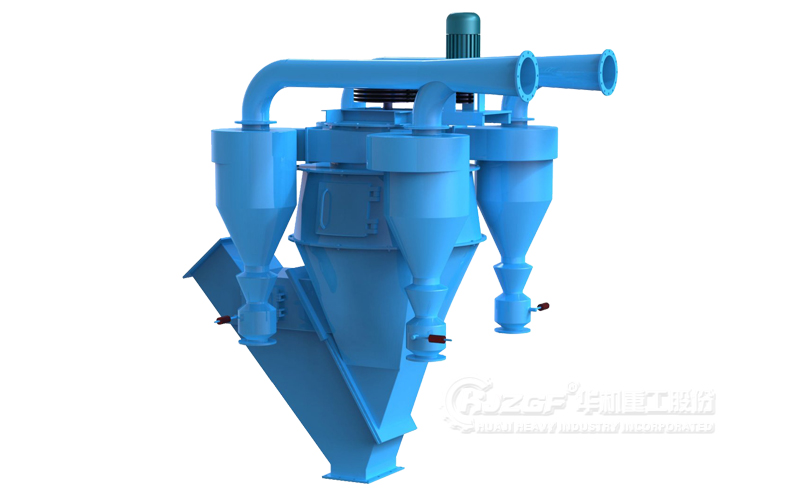

Efficiently Powder Selector

Maximum feed:<40目

production capacity:

Features:With stable performance, high efficiency of powder selection, convenient fineness adjustment, energy saving and environmental protection, long service life, etc., it is the ideal equipment for dry powder separation at present.

Applicable materials:It is suitable for sorting materials such as cement, calcium powder, titanium dioxide, silica micropowder, construction waste and so on. Widely used in cement, new building materials, environmental protection, rubber, ceramics and other industries.

24-hour service hotline

Efficiently Powder Selector product description

High-efficiency powder selecting machine is a successful scientific and technological product developed on the basis of introducing foreign high-efficiency powder selecting machine technology and adopting aerodynamic analysis method. The product integrates the plane vortex classifying principle of common powder separator and the finished product collection method of cyclone dust removal, so that the high efficiency off-vortex powder separator has the features of stable performance, high powder selecting efficiency, convenient fineness adjustment, energy saving and environmental protection, long service life and so on, which is the ideal equipment for the separation of dry powder at present. It is suitable for separating materials such as cement, calcium powder, titanium dioxide, silica micropowder, construction waste and so on. Widely used in cement, new building materials, environmental protection, rubber, ceramics and other industries.Efficiently Powder Selector working principle

When the high-efficiency powder selecting machine is working, the electric control system is opened, the variable speed motor drives the main shaft to rotate through the transmission device, the materials enter the center of the powder selecting room through the inlet located in the upper part of the room, and then through the special drop tube to the lower part of the room with the main shaft rotating spreading disk, the logistics in the high-speed rotating spreading disk under the action of the material, spreading uniformly in all directions, in the outside world under the action of the circulating fan generated by the high-speed rotating airflow to the high-speed spreading of materials for strong dispersion. Under the action of high-speed rotating airflow generated by the external circulating fan, the materials are strongly dispersed, and the coarse and heavy particles in the materials are thrown to the wall inside the powder selecting chamber by the action of inertia centrifugal force, and then they lose kinetic energy after collision and slide down along the wall to the coarse powder cone, and the rest of the materials are blown by the rotating airflow to continue to rise, and part of the coarse particles are selected to fall into the coarse powder cone after the large wind blade area.

The material after being sorted twice by the spreading disk and the big wind leaf continues to rise into the plane eddy current grading area. High-efficiency vortex separator dusty airflow in the rotating cage rotor formed by a strong and stable plane vortex effect, so that does not meet the requirements of the finished product of coarse powder is further selected precisely, because the inertial centrifugal force generated by coarse particles is greater than the vortex centripetal suction, the coarse particles are thrown around the vertical guiding blade, after impact, the loss of kinetic energy, falling into the coarse powder cone, by the coarse powder locking valve to exclude. The fine powder that meets the requirement enters the separator arranged around the powder selecting room with the circulating wind and is collected.

Efficiently Powder Selector Technical Parameters

| Model |

Product fineness RO.08(%) |

Processing air volume (m³/h) |

Rev (rpm) |

Motor power (KW) |

Maximum processing capacity (t/h) |

yield (t/h) |

| PS-20 | 2-5 | 16000 | 250-500 | 15 | 50 | 10-18 |

| PS-30 | 2-5 | 22000 | 220-450 | 18.5 | 90 | 15-28 |

| PS-40 | 2-5 | 30000 | 180-400 | 22 | 120 | 20-40 |

| PS-50 | 2-5 | 45000 | 160-340 | 37 | 150 | 30-50 |

| PS-60 | 2-5 | 60000 | 130-300 | 55 | 180 | 40-60 |

| PS-70 | 2-5 | 75000 | 130-260 | 75 | 260 | 50-80 |

| PS-80 | 2-5 | 95000 | 120-240 | 110 | 330 | 75-110 |

| PS-90 | 2-5 | 120000 | 110-200 | 110 | 400 | 95-130 |

| PS-100 | 2-5 | 150000 | 110-180 | 132 | 500 | 110-160 |

- durable

- make fast

- easy maintenance

- Few faults

- 24-hour sales hotline:+8618053687318

- get a quote

Recommended Products

Hotline:+8618053687318click to call

Copyright: Shandong Huaji Heavy Industry Co., Ltd. 24-hour service hotline:+8618053687318 E-mail:jczg@sdjiuchang.com