Shaper

Maximum feed:<55mm

production capacity:70-600t/h

Features:It is characterized by uniform particle size, good particle shape, large processing capacity, long replacement cycle of wearing parts and reliable operation.

Applicable materials:Suitable for shaping of stones (aggregates).

24-hour service hotline

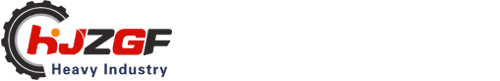

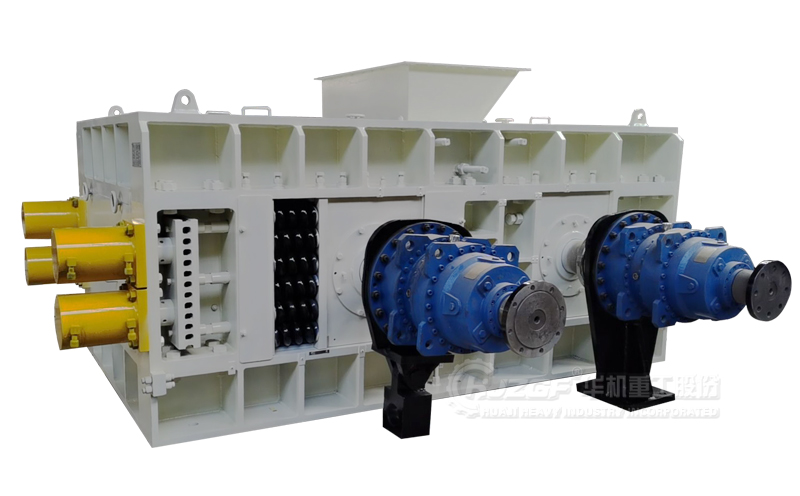

Shaper product description

The sixth-generation shaping sand making machine developed by our company integrates crushing and shaping in one machine, which is composed of body, rotor, bulk plate, hydraulic device, electric motor, impact block and circumferential guard plate. It adopts the dual-purpose bulk material tray which is convenient for the conversion of stone to stone and stone to iron; the optimized rotor flow channel with deep cavity greatly improves the material throughput. The diamond-shaped impact block reduces the wear and effectively protects the vertical plate. Adopting special sealing structure; equipped with hydraulic device is convenient for overhaul and maintenance. This shaping sand making machine is characterized by uniform particle size, good grain shape, large handling capacity, long replacement cycle of wearing parts, reliable operation and so on. It is suitable for the medium and fine crushing operation of various ores and rocks, such as iron ore, non-ferrous metal ores, adamantine, bauxite, quartz sand, brown corundum, perlite, basalt and other high hardness materials.

It can be widely used in mechanism sand, mining, metallurgy industry, as well as highway, railroad, bridge, hydropower, mineral grinding and other industries.

Shaper working principle

The material can be directly into the rotor by centrifugal acceleration and thrown out, and collision with the perimeter guard plate crushing, but also through the bulk tray diversion, part of the scattering from all around, the other part of the rotor into the accelerated sprint out of the collision and friction with the surrounding scattered materials, and with the perimeter guard plate collision, rebound, the formation of a cycle of strikes. With the crushing, small particles of material in the vicinity of the perimeter guard plate gradually formed material layer curtain, improve the crushing effect, and play a protective role for the equipment, the finished product meets the specifications from the lower end of the discharge port.Shaper Technical Parameters

| Model | sand making | plastic surgery | sand making | plastic surgery |

Motor power (KW) |

|

Maximum feed size (mm) |

throughput (t/h) |

||||

| ZX-150 | <30 | <35 | 70-140 | 130-240 | 2×75 |

| ZX-180 | <30 | <35 | 80-120 | 150-280 | 2×90 |

| ZX-250 | <35 | <40 | 100-150 | 200-300 | 2×110 |

| ZX-300 | <35 | <40 | 100-150 | 240-380 | 2×132 |

| ZX-350 | <40 | <45 | 120-180 | 250-350 | 2×160 |

| ZX-400 | <40 | <45 | 150-240 | 350-450 | 2×200 |

| ZX-500 | <45 | <50 | 350-380 | 400-500 | 2×250 |

| ZX-600 | <50 | <55 | 380-450 | 450-600 | 2×315 |

- durable

- make fast

- easy maintenance

- Few faults

- 24-hour sales hotline:+8618053687318

- get a quote

Recommended Products

Hotline:+8618053687318click to call

Copyright: Shandong Huaji Heavy Industry Co., Ltd. 24-hour service hotline:+8618053687318 E-mail:jczg@sdjiuchang.com