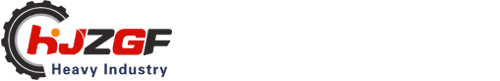

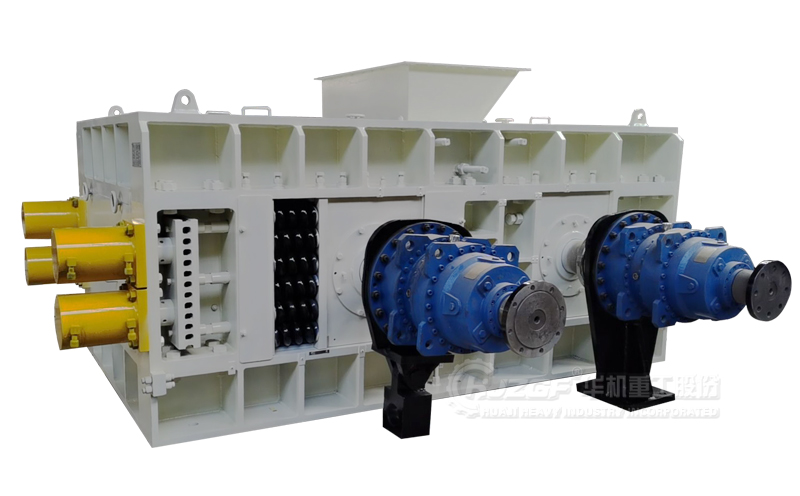

Three Roll Crusher

Maximum feed:<90mm

production capacity:5-300(t/h)

Features:The use of low maintenance costs, large crushing ratio, reliable performance, less dust, low noise and so on.

Applicable materials:Fertilizer, coke, coal, cement clinker, ceramic raw materials, limestone, feldspar, water slag, quartzite, gypsum, clay, salt, chemical raw materials and other solid materials.

24-hour service hotline

Three Roll Crusher product description

Three-roll crusher is suitable for fine crushing of solid materials with compressive strength less than 240Mpa and water less than 20%, such as chemical fertilizer, coke, coal, cement clinker, ceramic raw materials, limestone, feldspar, water slag, quartzite, gypsum, clay, salt, chemical raw materials and other solid materials. It is characterized by low maintenance cost, large crushing ratio, reliable performance, low dust and low noise.

Three rolls crusher is equipped with three crushing rolls, according to the crushing size required by the user, the three roll surfaces are arbitrarily selected from the combination of surfacing roll surface and flat roll surface.

Three-roll crusher is suitable for fine crushing operation with feed size less than 90mm and finished product size 0.2-10mm, such as fertilizer crushing in chemical fertilizer factory, feldspar crushing in ceramic industry, cement clinker crushing in cement factory and water slag crushing in cement factory, quartz crushing in quartz industry, iron ore crushing in iron ore mining industry, chemical crushing in chemical industry, etc.; or crushing occasions similar to those mentioned above. This equipment can be changed to diesel engine and gasoline engine as power in the case of no electricity.

Three Roll Crusher working principle

Three-roll crusher utilizes three high-strength wear-resistant alloy crushing rolls, which rotate relative to each other to generate high squeezing pressure to crush materials. After entering the upper two-roll crushing chamber and being squeezed by the relative rotation of the two rolls, the materials will be squeezed and ground for the first time (coarse crushing), and then the materials will immediately enter into the relatively rotating lower two-rolls (the middle rolls are common rolls), where they will be squeezed and ground for the second time by squeezing pressure of the lower two-rolls (fine crushing), and crushed into the required granularity by discharging from the discharge port.Three Roll Crusher Technical Parameters

| number | Specification |

Feed size (mm) |

Output granularity tunable(mm) |

production capacity (t/h) |

Motor power Kw |

Protection mode |

| 1 | 3PG-15PT | <40 | 1-10 | 10-60 | 30-60 |

sprung or hydraulically |

| 2 | 3PG-30PT | <40 | 1-10 | 20-90 | 44-90 | |

| 3 | 3PG-45PT | <40 | 1-10 | 30-140 | 60-100 | |

| 4 | 3PG-55PT | <60 | 1-10 | 20-120 | 75-110 | |

| 5 | 3PG-75PT | <60 | 1-10 | 30-160 | 100-150 | |

| 6 | 3PG-90PT | <60 | 1-10 | 50-260 | 130-170 | |

| 7 | 3PG-100PT | <90 | 1-10 | 30-160 | 160-250 | |

| 8 | 3PG-120PT | <90 | 1-10 | 50-200 | 180-260 | |

| 9 | 3PG-140PT | <90 | 1-10 | 60-300 | 290-360 |

- durable

- make fast

- easy maintenance

- Few faults

- 24-hour sales hotline:+8618053687318

- get a quote

Recommended Products

Hotline:+8618053687318click to call

Copyright: Shandong Huaji Heavy Industry Co., Ltd. 24-hour service hotline:+8618053687318 E-mail:jczg@sdjiuchang.com